Zhejiang HydroT Tech Co., Ltd. was founded in July 2016., which headquater located in Hangzhou. With the mission of "create a green life driven by hydrogen energy", HydroT focuses on the research and development, production, sales and related engineering services of hydrogen fuel cells.

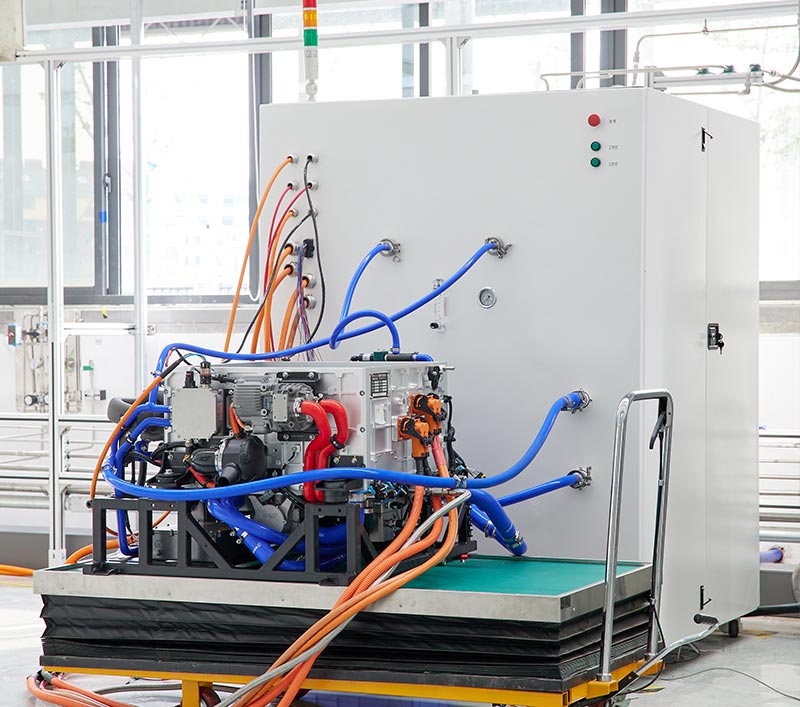

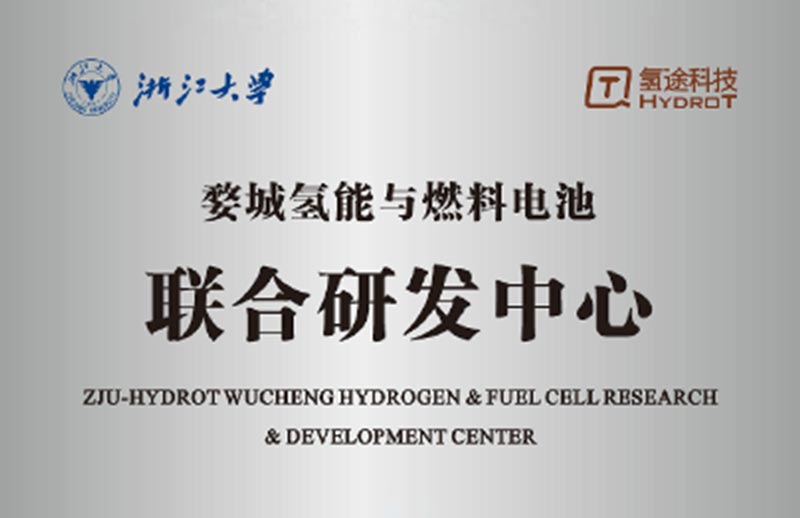

The company owns a high-quality, professional R&D team, which covers electrochemistry, control, structure, electrical, simulation, materials and other disciplines. More than 50% of the members are graduate-level specialist. The company has established a relatively mature process and system for product developing, as well as a complete capability of parts verification and product testing. It has established a joint R&D center for hydrogen fuel cells with Zhejiang University and a post-doctoral workstation.

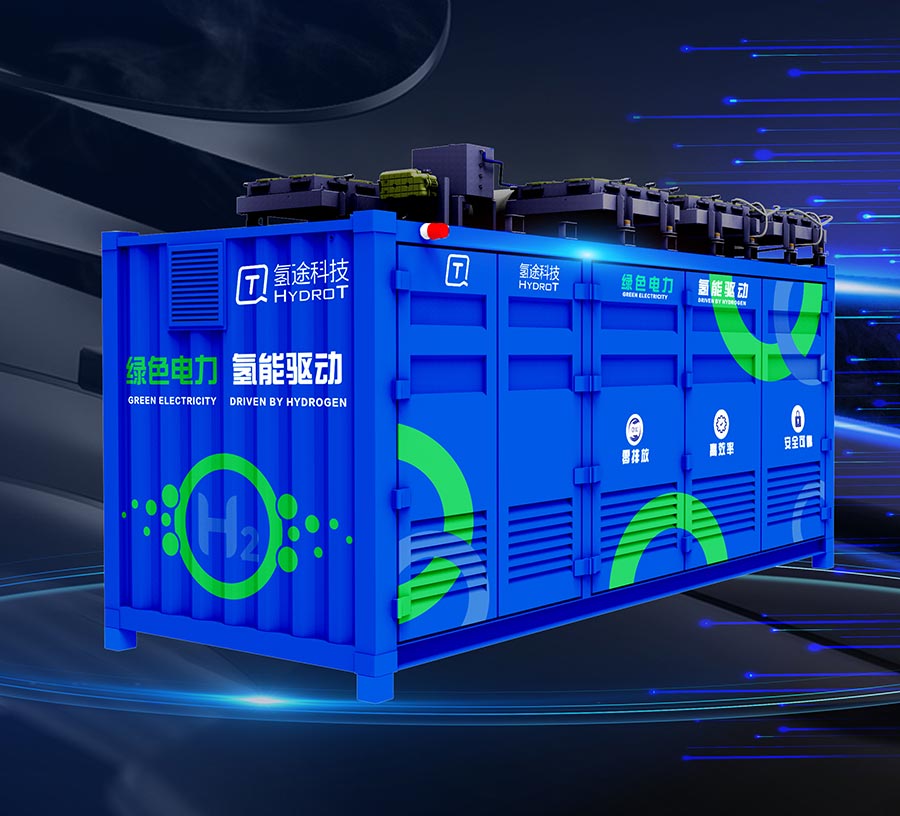

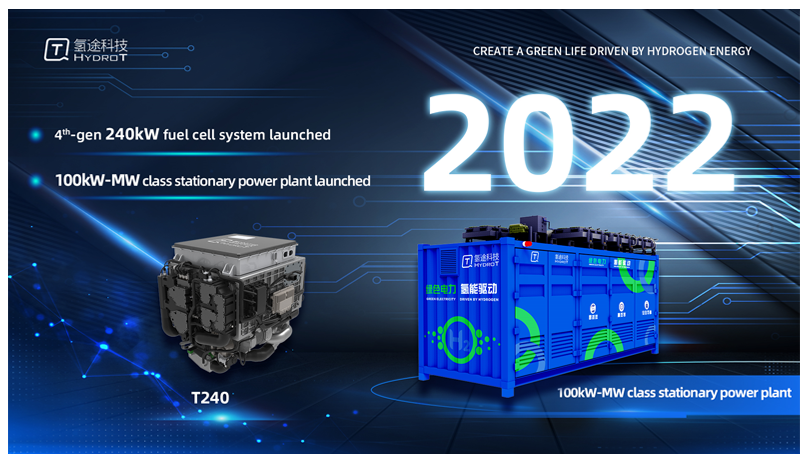

After years of product iteration, the fuel cell system developed by the company has outstanding advantages in key parameters such as power output, hydrogen utilization rate, power density, environmental adaptability, reliability and operation lifetime. In addition, the company mastered core technologies in components such as controller, reactor, hydrogen supply and circulation subsystem.

The company's industrial production base, with a capacity of 5000 units per year, produces in strict accordance with the quality requirements of automotive parts, with the characteristics of flexibility and digitization. Using the electricity generated during the fuel cell test, the base's electricity consumption meets the standard of a zero-carbon plant.

The company has built in-depth cooperation with more than ten well-known automobile enterprises such as Dongfeng, Jinlong and Zhongtong, covering more than ten provinces such as Yangtze River Delta, Pearl River Delta, Central China, North China and Southwest China. The quality of products has been highly recognized by customers. In addition to the on-road vehicles, the company actively explores other application of fuel cells in forklift trucks, distributed generation and other fields.